Lobster slice production process

2024-08-24 06:00:55

Lobster slices are prepared by seasoning fresh starch-enriched fish and seasonings by steaming, drying, and drying. Its products are in short supply. Suitable for township enterprises and self-employed people to invest in production.

First, the raw material selection of fresh fish, head and tail, internal organs, wash with water, take about 50% of its net meat. Recipe: 45 kg of starch, 5 kg of fish, 1 kg of monosodium glutamate, 1.65 kg of sugar, 1.15 kg of salt, 250 ml of cinnamon (250 g of cassia, 250 g of licorice, and 250 g of star anise) to 1 kg. Another 5 kg of starch, 19 kg of water, beaten.

Second, the deployment of raw materials, monosodium glutamate, water and then open. The starch is beaten with water, and the mixture is steamed. The mixture is blown while stirring. It must be hot, thick, and transparent. If you want to color fish, you can add the right amount of food coloring.

Third, beaten the moromi strip raw materials, seasoning ingredients and pulp at the same time put the beater, and then gradually add the hot slurry, beaten for about 20 minutes until the uniform, remove the pour into the wooden box, cover with a cloth and heat, then Gradually chop the slivers on the wooden table. Make sure that they are strong and have no holes in the middle. The diameter of the sliver is 5 cm.

4. Cook the slivers on the steamer shelf for about 1 hour and then place them on the table for 12 hours.

5. Cooling section Place the cooling strips in a precooling chamber at 0 to 2°C for about 30 hours. When the chips are hardened to a stick shape, they can be sliced ​​with a slicer to a thickness of 1 mm.

6. Drying The sliced ​​fish will be blown, sun dried or dried.

First, the raw material selection of fresh fish, head and tail, internal organs, wash with water, take about 50% of its net meat. Recipe: 45 kg of starch, 5 kg of fish, 1 kg of monosodium glutamate, 1.65 kg of sugar, 1.15 kg of salt, 250 ml of cinnamon (250 g of cassia, 250 g of licorice, and 250 g of star anise) to 1 kg. Another 5 kg of starch, 19 kg of water, beaten.

Second, the deployment of raw materials, monosodium glutamate, water and then open. The starch is beaten with water, and the mixture is steamed. The mixture is blown while stirring. It must be hot, thick, and transparent. If you want to color fish, you can add the right amount of food coloring.

Third, beaten the moromi strip raw materials, seasoning ingredients and pulp at the same time put the beater, and then gradually add the hot slurry, beaten for about 20 minutes until the uniform, remove the pour into the wooden box, cover with a cloth and heat, then Gradually chop the slivers on the wooden table. Make sure that they are strong and have no holes in the middle. The diameter of the sliver is 5 cm.

4. Cook the slivers on the steamer shelf for about 1 hour and then place them on the table for 12 hours.

5. Cooling section Place the cooling strips in a precooling chamber at 0 to 2°C for about 30 hours. When the chips are hardened to a stick shape, they can be sliced ​​with a slicer to a thickness of 1 mm.

6. Drying The sliced ​​fish will be blown, sun dried or dried.

Innovative Fin Flood Barrier 2023 Debut

Denilco second generation sole patented flood fin barrier

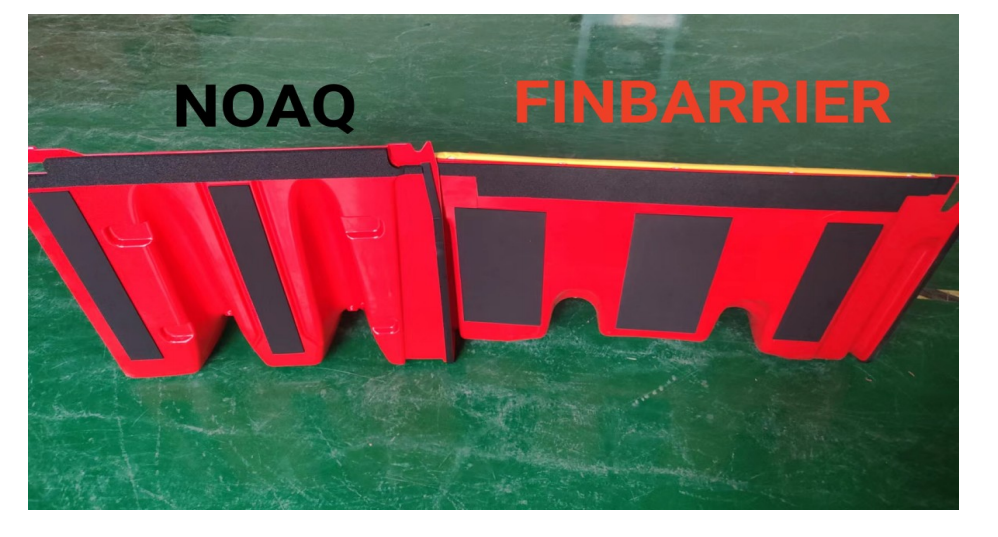

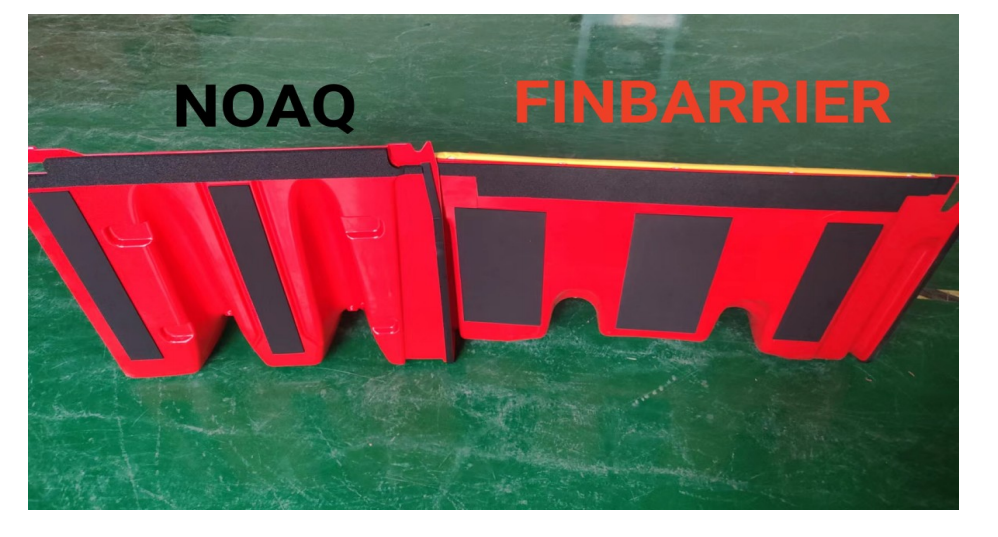

Our finbarrier's advantages over NOAQ is:

1. The featured more scientific Arched front face design offers 20% to 30% more anti-flood ability.

2. The concave-convex side face brings better sealing and stability.

3. Back side's removable structure and support bars could prevent barrier from moving under heavy wave

and wind and provide more anti-flood support.

4. World's first style of flood barrier that can be used in uneven areas such as sand&stone&soil&lawn,etc

5. Spring lock structure is more convenient to install and more stable

6. Much bigger waterproof strips and anti-slip strips than NOAQ's.

Q&A:

What is the yellow part ?

We call the yellow part Fin, Fin can be connected through velcro stickers, there is

a counterweigh structure in front of the fin.

What is the material of yellow part and how long it could be used under sunshine?

The fin is made of a kind of patented chemical fiber composite material which could be

used 3 to 5 years under constant sunshine according to our lots of tests under both high

and low temperature.

What is the function of Fin?

The main function of Fin is to prevent water leakage and creates a even layer when there

is uneven ground. And of course Fin could also be used in even grounds.

Innovative Fin-type Flood Barrier,Innovative ABS Flood Barrier,Flood Mitigation Barrier,Denilco Flood Barrier

Denilco Environmental technology(Suzhou)Co., Ltd. , https://www.wflood.com